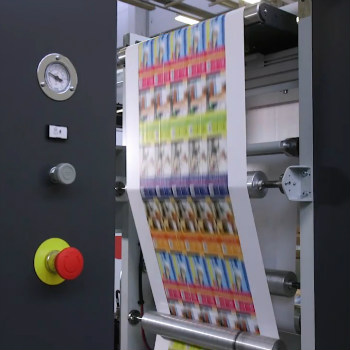

An interesting collaboration between Kodak and Uteco created a hybrid flexible packaging press powered by Kodak’s continuous inkjet technology. It aims to break the conception of digital package printing being assigned to short runs, and create cost effective, high speed and quality production length printing.

Uteco recently purchased Kodak’s latest inkjet printing system featuring ULTRASTREAM technology to create the Uteco Sapphire EVO. Through this transaction, Uteco will be one of the first equipment manufacturers to utilize the technology for flexible packaging.

Kodak first debuted their ULTRASTREAM technology at Drupa 2016 with development plans for availability in 2019. The continuous inkjet technology delivers 600 x 1800 dpi with production speeds of up to 150 mpm, and uses environmentally-friendly and economic water-based inks on paper and plastic.

Kodak first debuted their ULTRASTREAM technology at Drupa 2016 with development plans for availability in 2019. The continuous inkjet technology delivers 600 x 1800 dpi with production speeds of up to 150 mpm, and uses environmentally-friendly and economic water-based inks on paper and plastic.

With ULTRASTREAM, Kodak plans to extend its reach into all packaging segments, and by joining forces with Uteco, it will be used to expand Kodak’s footprint into new segments.

Main features of the Sapphire EVO:

- Powered by KODAK Stream Inkjet Technology

- Water-based inks

- High speed, prints up to 300 mpm on paper and plastic

- Cost effective – for run lengths up to 20,000 square meters

Here’s an extended look at flexible packaging printing technology:

Kodak Leaps Ahead in the Inkjet Flexible Packaging Market